03-5577-2947

Weekdays: 9:30- 18:00

For Lenses Precision molding simulation

セラミックフォーラム株式会社 > Ceramicforum Co., Ltd. > Products > Glass Melting Technology Department > Analysis / Simulation Service > For Lenses Precision molding simulation

SimPGM -Simulation software for lens precision molding

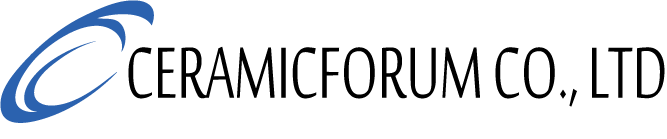

SimPGM is an "easy to use" simulation software for precision press glass molding processes.

By using this simulation software, the mold forming process can be predicted, and glass precision press molding technology can be widely utilized.SimPGM can further enhance possibilities for the design of your product.

Manufacturer Profile

Fraunhofer Institute for Production Technology (Germany)

- Production Technology Laboratory

- SimPGM lens precision molding simulation tool

- 2D, 3D simulation

- lens molding process development

- lens molding process development

Features of SimPGM

Easy to Use Graphic Interface

- Display (laser TV, projector)

- lighting (white LED, UV LED)

- energy-saving devices (high efficiency, high voltage, high temperature operation)

- storage device (blue laser diode)

- radio system (high frequency devices)

Concept of Easy to Use Software

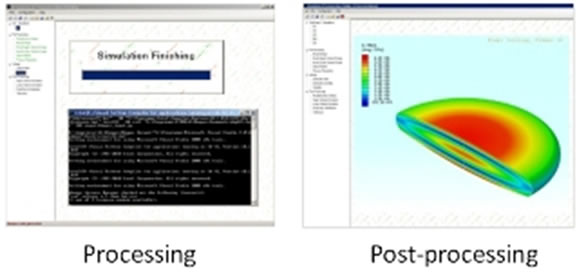

- Able to accommodate various types of press machine

- glass blanks of various shapes and molds

- and can deal with various molding processes

Predictable Molding Process

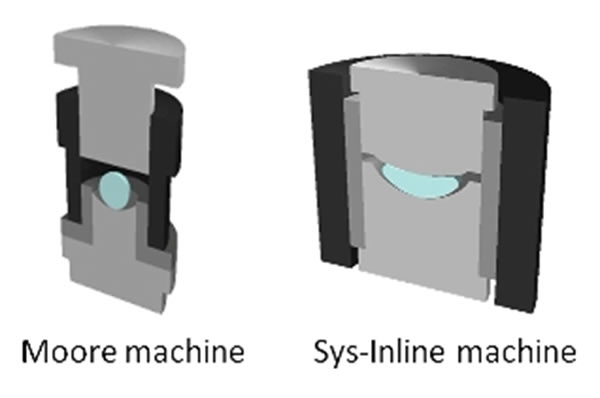

- Material flow in the molding process

- distribution of strain and temperature

- change in the refractive index during the cooling process

- error generation due to contraction

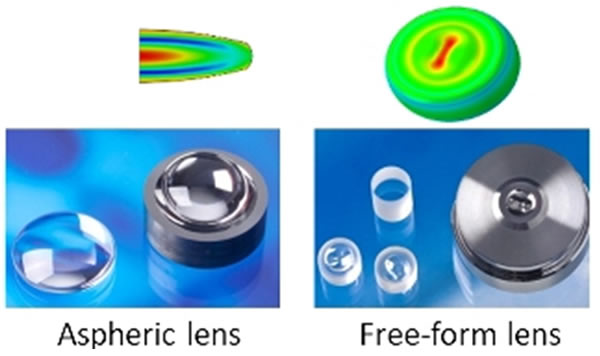

Steps for more sophisticated mold forming - Flexible Mold Design

- 2D axisymmetric aspherical lens

- 3D free-form lens

- 3D wafer level optical device

- 3D wafer level optical device

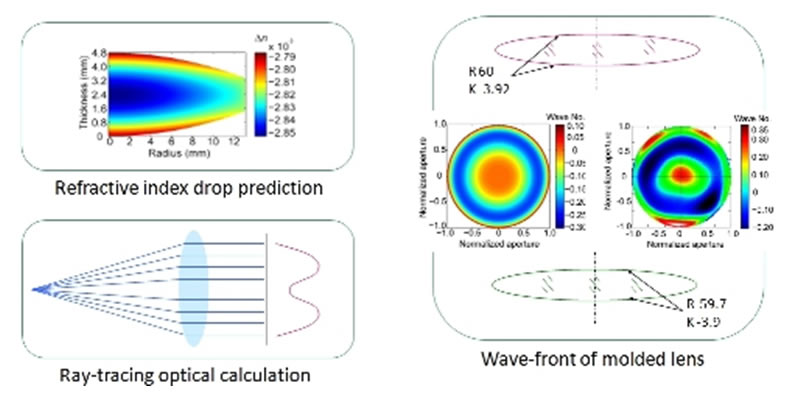

Comprehensive Optical Design is Possible

By changing the lens shape from the design stage, the effects of a decreasing refractive index can beeliminated:

- predicting of decrease in refractive index by finite element method

- calculation of wave front and focal length

- correction of optical properties by shape change

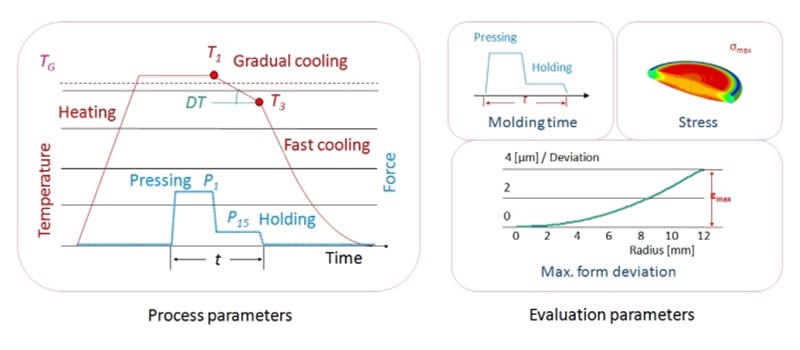

Effective Process Optimization

By using this software to optimize the mold forming process, labor and expenses can be greatly reduced.Conventionally, such work required several days, but with this software, it can be done in just a few hours.

- Minimization of necessary process parameters

- necessary evaluation parameters

- and evaluation parameters

For any questions or requests regarding our services please feel free to contact us via phone or inquiry form.

For Telephone Inquiries

03-5577-2947

Weekdays 9:30-18:00

For WEB Inquiries