SiC Device Foundry Services

Features of SiC Device Foundry Services

Ascatron offers total solutions for SiC power device development.From the design stage of SiC device planning, to prototyping, evaluation, pilot production and large-scale mass production, Ascatron furnishes customers with optimum solutions for each stage.At the KTH Royal Institute of Electronics, Sweden, Ascatron has a 1300 m2 clean room, where they make Epi up to 150 mm wafers, and device prototypes.

Beginning with the announcement of the 4.5 KV PiN-Diode in 1999, there has been a profusion of developmental results, especially in high voltage power devices, developed and prototyped according to our customer's design, such as SiC diode with embedded p-region, SiC-IGBT, SiC-SJ type MOSFET etc.Ascatron also undertakes manufacturing with specific processes such as embedded epi, trench layer formation, heat treatment, SJ structure formation etc.

SiC Device Process Service

- SiC device development (from design to prototype evaluation)

- In process epitaxy (embedded & buried structures, multilayer pn junction deposition etc.)

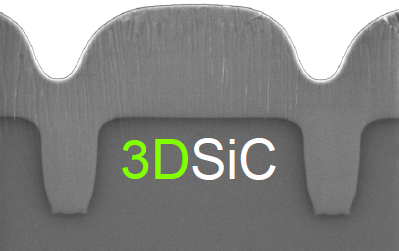

- Trench layer formation (trench structure depth 10μm * width 2μm, voidless re-deposition)

- Oxide-film formation (vapor deposition and high temperature annealing combination)

- Metallic film formation (formation of various types of metal layers + protective layers)

Ascatron owned facility (in part)

Kista factory

- Epitaxy – 3 hot-wall SiC CVD reactors

- Lithography – 0.5 µm stepper

- Dielectrics – Thermal, LTO, PECVD, ALD

- Implantation – Al, B, N, P – 650 keV

- Metals – Ti, TiW, Al, Au, Pt, Ni, & silicides

- Anneal – RTA, high temp furnace (1900°C)

- Etching – ICP, RIE

- Post Process – dicing & wire bonding

- Metrology & Electrical characterisation

Product Manufacturer's Guide

II-VI Kista AB (Coherent Group)(Sweden)

Coherent (Sweden) is an SiC-specified foundry founded in 2011 able to process SiC from epitaxy to device design and packaging.

A spin-off venture from Swedish national research institute ACREO, Coherent is still located at the same research institution and conducts R&D for SiC since 1993. Due to unique expertise based on development results, Ascatron provides 3D SiC epitaxial structure, device design, process technology etc. as well as know-how and technology only available from their company.